Serial tech entrepreneur in commercial real estate, education, and e-commerce to drive awareness and demand for low carbon concrete and high-quality carbon removals

LOS ANGELES (December 8, 2021)

CarbonBuilt today announced that Cindy McLaughlin, a serial entrepreneur who has founded, built, and led technology companies in commercial real estate, education, and e-commerce, has joined the company as Head of Product.

In this role, McLaughlin will expand awareness of CarbonBuilt’s low carbon concrete products, and the removal of carbon dioxide emissions that result from their production.

She will work at the intersection of real estate, infrastructure, government policy, and carbon markets to help build a future where low- or negative-carbon concrete is the norm, rather than the exception.

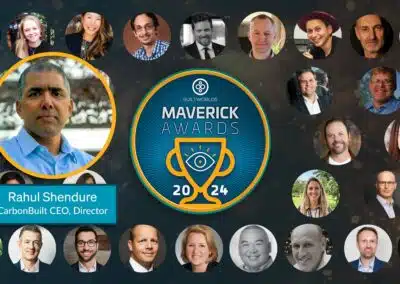

“Cindy’s experience as an entrepreneur in real estate and other sectors, combined with her commitment to make an impact on combating the climate crisis, make her a perfect fit for our growing company,” said Rahul Shendure, CEO of CarbonBuilt.

“While the products we make are very traditional, customer demand for reduced embodied carbon, concrete’s potential as a tool for carbon mitigation, and policymakers’ response to this potential are all very new. These require a fresh, creative approach to product development and marketing.”

Before joining CarbonBuilt, McLaughlin was founding CEO of Envelope, a hyperlocal acquisitions analytics company for commercial real estate.

She is co-chair of the Tech and Innovation Council of the Urban Land Institute of New York City (ULI) and serves on the Editorial Board of Propmodo.

Prior to founding Envelope, McLaughlin held leadership roles in a variety of companies, including President, Content + Consumer for American Prison Data Systems, a company focused on educational software for incarcerated communities and co-founder and CEO of Style for Hire.

McLaughlin holds a Bachelor of Arts in International Relations from Mount Holyoke College and a Master in Business Administration, with a focus on technology and strategy, from the Massachusetts Institute of Technology.

CarbonBuilt’s Reversa™ formulations replace most or all of the Portland cement used in concrete products with widely-available materials, reducing raw materials cost and embodied carbon simultaneously.

During the curing process, CO2 taken directly from industrial sources, biomass or emerging direct air capture solutions is permanently sequestered in the concrete.

Together, these changes result in a 10 to 30 percent reduction in raw material costs and a 60 to 90 percent reduction in carbon dioxide emissions, all while producing products that meet existing specifications.

ABOUT CARBONBUILT ULTRA-LOW-CARBON CONCRETE

CarbonBuilt, winner of the NRG COSIA Carbon XPRIZE, mineralizes CO2 from industrial, biomass, and direct air capture sources into low-cost, low-carbon concrete formulations. Its proprietary process reduces overall CO2 emissions by 70-100+ percent while delivering industry-standard products that yield higher margins for concrete producers. More information is available at www.carbonbuilt.com.